mod. GX swivelling turret structure

The Gx range of RM hose-reel irrigation machines features a swivelling turret structure, which, by rotating on the fixed bottom frame, allows the reel to be steered towards the desired direction to unwind the hose.

The machine is outfitted with duly oversize telescopic brackets to allow a high anchoring on any kind of ground. They are operated by self-balancing hydraulic cylinders with safety valves, and they ensure the required stability.

The transverse width of the highest reel allows to considerably lower the overall height of RM machines and their barycentre, thus making them among the stablest ones on the market.

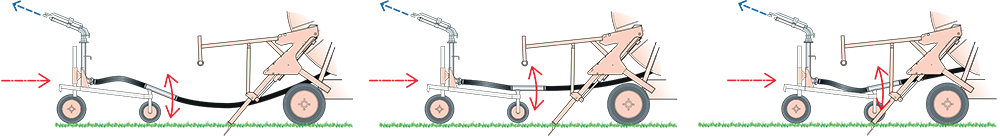

Starting from the 790Gx model the machine can be equipped with (optional) the rear unwinding arm of PE hose, by fastening the sprinkler trolley to the ground and towing the irrigation machine. This solution allows unwinding the hose by cancelling the friction on the ground, and exploiting the tracks already present in crops.

The 890Gx, 990Gx and 1000Gx models feature a great clear span of the frame with reference to the ground, thus preventing the underlying crops from being damaged during the hose unwinding.

Monolithic RM frames are free from any screwed structural elements, manufactured in a single block and hot-dip galvanized, designed through a three-dimensional calculation system.

Download the general catalog |

|

ENERGY EFFICIENCY WITH CONSUMPTION REDUCTION, thanks to RM Turbo-Reducers

|

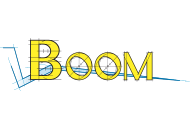

The energy required to rewind the hose is the decisive element in the economy of the self-propelled irrigation machines: RM Turbo-Reducer Unit with in-built water By-Pass and four-speed gearbox drastically reduces pressure losses during the irrigation phase, thus ensuring money saving determined by less energy consumption. The design of the turbine impeller is the result of a cutting edge aerodynamic calculation which allowed reaching an extraordinary channelled flow of the liquid without any turbulence, thus ensuring the operation with a minimum pressure of 1.5 bar at machine inlet. The quality of the Turbo-Reducer Unit is obtained by using all the movable internal parts in stainless steel, such as all bearings (including the ones of the turbine axle) in class A dipped in oil bath. The system includes a built-in automatic brake that engages during hose unwinding and disengages during rewinding. Moreover, at the end of rewind the Turbo-Reducer positions the “Operation-Stop” lever to the correct position for the following hose unwind. The exclusive RM Power Save™ system allows for a practical, quick speed change even during the normal hose rewind with water under pressure, thus immediately reducing the turbine rotational speed without having to act on the electronic programmer controls. RM Turbo-Reducer Unit does not require any periodic maintenance. Moreover, at the end of sprinkling process every liquid residue is automatically ejected from the turbine body. |

ACCURACY IN ROTATION, by means of chain drive

|

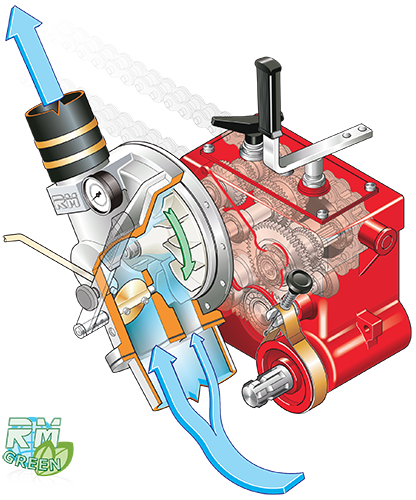

Another remarkable characteristic of RM hose-reel irrigation machines: starting from the 581 Gx Evo model the drive between turbo-reducer and reel is manufactured with high-tensile strength ARNOLD STOLZEMBERG® chain with extruded rollers and without extension. Moreover, by using the adjustable toothing (another exclusive of RM) located in the outer reel diameter, a very high transmission gear ratio is created between the wheel and turbo-reduction gear in order to drastically reduce the energy absorption for rewind as well as the turning moment in the reduction gear output shaft, thus preserving its duration in time. |

|

In the 1000 Gx and MAGNUM Fx models drive chains are located on both reel sides in order to also cancel the torque effect of reel.

REEL AXLE: the best technology available in the market

|

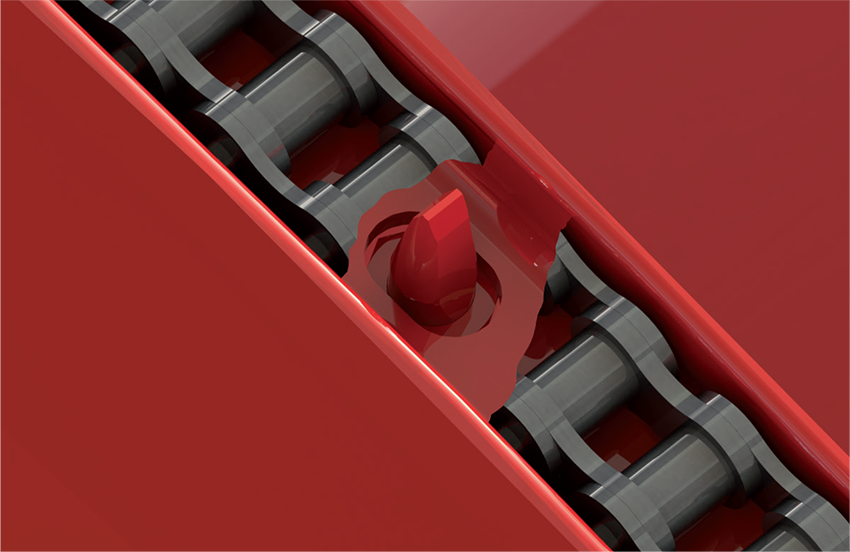

Reel mass with its hose in polyethylene wound and filled with water reaches 80% of machine weight. Supports on which reel rotates are subject to very high loads, thus generating high frictions, which must be minimized in order to reduce the effort required for the movement. Already starting from the 540 Gx model RM reel axle is:

|

This technology – an exclusive of all RM models – is applied to the whole range, including the cheapest models.

INTUITIVE OPERATION by means of RM RainMaster 2.6 programmers

|

RM electronic programmers were designed to be perfectly built into the irrigation machine. They are simply to use and feature an intuitive, multilingual display; it can be easily bypassed without interrupting the machine irrigation cycle in order to switch from automatic to manual operation. Electromechanical drain and/or shut-off valves, GSM modem, solar panel for battery and anemometer recharge are available as optionals. The optional additional gun of rewind end can be controlled as well. |

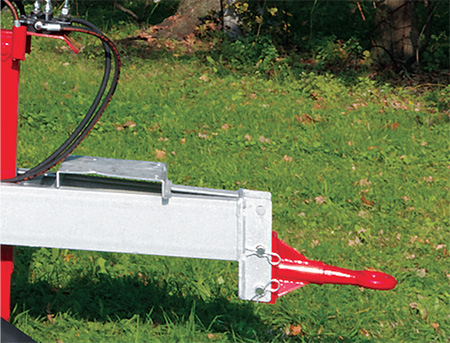

AN EXCEPTIONAL GRIP by means of height-adjustable towing hitch eye |

|

|

A partire dal modello 690 Gx Evo il timone è dotato dell’occhione di traino regolabile in altezza e attraverso semplici spinotti. |

MULTI-SECTION TECHNOLOGY for an indestructible reel structure

|

Starting from the 581Gx model the reel resorts to the multi-section ribbed technology fitted with sides completely made up of high strength DOMEX 420™ sheet with yield load to 420 kg/mm2, made up of wedges precut by means of HD Laser system and then assembled through robotic welding. This leads to a high resistance to bending stress, despite the reel lightness, and to an increase by 300% of the PE hose supporting surface on reel sides - a remarkable advantage compared to the outdated system of side tubular tires. The internal ferrule is made up of calendered flat sheet, which helps preserve, then extend the duration of the polyethylene hose in the course of time. |

The 890 Gx , 990 Gx models feature the “tapering profile” side reel section, so that all side bends can be effectively counteracted even during the most difficult rewinds.

Sections of each side were designed to be fully and thoroughly coated by the double-layer painting treatment even in the most internal parts. In that way steel does not deteriorate in the boxed or hidden parts. A side white segment allows checking the regular reel rotation even from a great distance.

MAXIMUM STABILITY AND DIRECTIONALITY UNDER ANY CONDITION, by means of RM rain gun trolleys

|

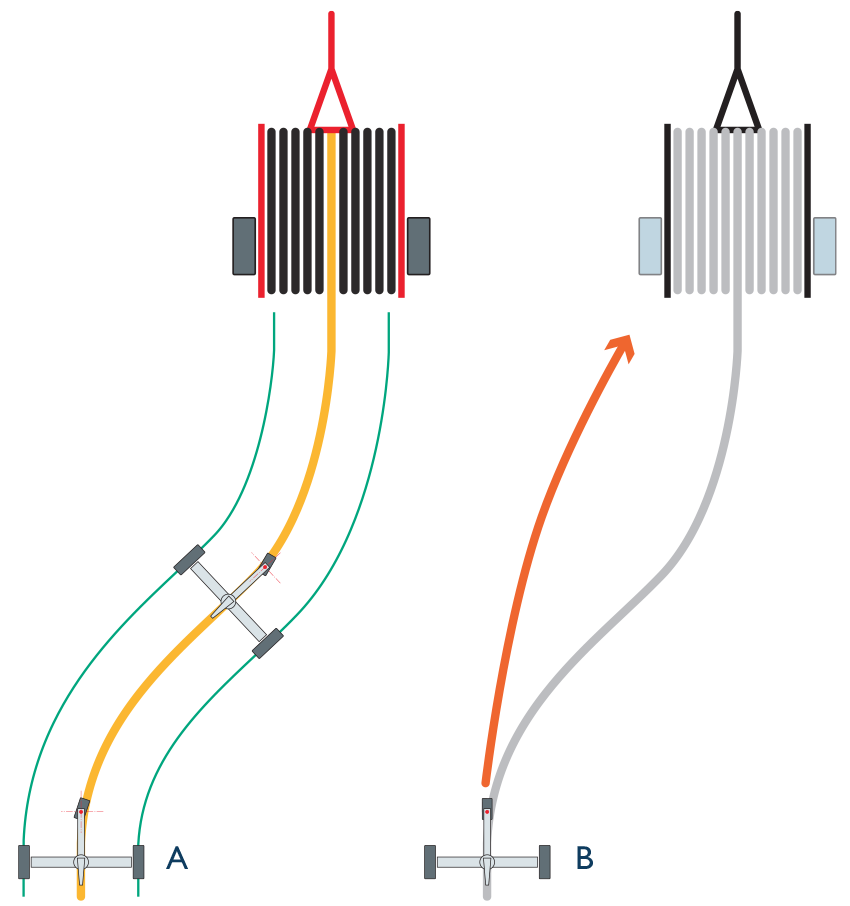

All the trolleys are available in the two- or four- fixed tyred wheel version and a steering pneumatics. This wheel allows the trolley to follow the irrigation hose in the position where it was unwound (fig. A), as being steering it is steered by the PE hose itself, thus eliminating the typical inaccuracy of the fixed middle wheel or slide trolleys that are not included in the ideal trajectory during the paths not perfectly straight (fig. B). Cast iron wheels with directional crests – expressly designed to be paired with the steering wheel – are supplied as optional. They increase the steerage and mass in the point where they are most required. Both wheels are fitted with hubs with tapering bearings and lubricator. The whole trolley structure is hot-dipped galvanized, thus ensuring an outstanding lifespan against corrosion. |

Customizable HYDRAULIC SYSTEM

Starting from the 570Gx Evo model, models are fitted with a complete hydraulic system for operating the rear hydraulic brackets and lifting the trolley. The hydraulic system can be implemented by means of hydraulic bar base, hydraulic rotation of turret, independent hydraulic lift of trolley (in the case of machines fitted with spraying boom) in all models.

|

In the irrigation machines outfitted with rear unwinding arm of PE hose a specific tilting bar supporting base suitably structured is used: it is useful for improving the anchoring to the ground during rewind. The following parts are available as optionals in place of the hydraulic tractor hose couple:

|

|

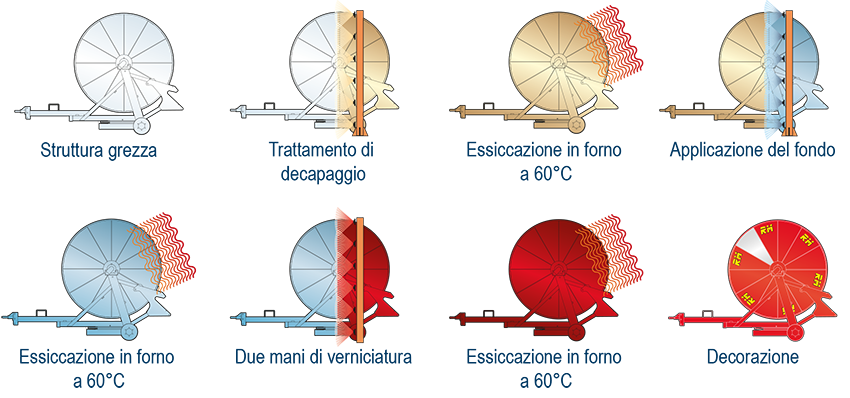

HIGHER RESISTANCE TO AGING thanks to RM painting cycle

A preventive pickling treatment is performed on the painted parts of all RM machines as well as a following painting process through a double-layer electrostatic system – which ensures a coating even in the most hidden machine parts – with highly eco-friendly water-based paints and primer. Each cycle is accompanied by an in-oven stabilization treatment at 60°C, thus obtaining surfaces which are highly resistant to corrosion and especially to UV rays.

DISTRIBUTION ALWAYS PERFECT even at the end of rewind

Starting from the 540 Gx model the rain gun trolley stops on the ground at the end of rewind, and the following hooking and lift are carried out in fully automatic mode, that is, without any minimal interventions by the operator. All rain gun trolleys are fitted with the tilting hose terminal in order to avoid any changes in the trim when trolley comes close to the irrigation machine, thus maintaining the correct gun position until the end of the irrigation.

DOUBLE AXLE WITH ASYMMETRICAL ROCKER ARM less effort on towing on every kind of ground

|

All the models of the 990Gx and 1000Gx series – and as optionals in the 690Gx, 790Gx, 890Gx – are fitted with double axle with isodiametric wheels feature the asymmetrical rocker arm. This solution allows for a remarkable reduction in towing on rough soils, which – accompanied by a reduced side overall dimensions – also ensures a better distribution of weight during the steering phase, thus making the machine handier than the axle. Machines can be outfitted with different sizes of tyres like the “Big Size” type ones. |

GUARANTEE OF RELIABILITY, as machines are tested one by one.

All RM machines are thoroughly tested before being shipped to the customer. They undergo both mechanical tests – to check their operation – and hydraulic tests by means of pressure water at 12 bar to check the accuracy of joints and connections and the resistance of various components to water pressure.

ATTENTION PAID TO THE ENVIRONMENT by means of state-of-the-art technologies

|

RM manufactures its machinery and equipment in compliance with the environmental protection. They use raw materials coming from eco-friendly, certified cycles; they use exclusively water-based paints; they implement technologies in order to reduce energy consumptions. Those are some of the principles determining the technical choices for RM hose-reel irrigation machines, believing that only an attentive approach to those themes – aimed at reducing pollutant emissions – makes the external environment cleaner and the work healthier for workers. |

Very high-quality POLYETHYLENE HOSE with differentiated thickness

All RM hose-reel irrigation machines feature the medium density polyethylene hose (PEMD) with differentiated thickness starting from ø 90 included; the highest thickness near the reel allows for a better accuracy on rewind and a less ovalisation due to hose bending.