All engine-driven pump and engine-driven clutch units of the MOP series are manufactured with new factory engines: FPT (Iveco), JCB, Deutz, J. Deere, Perkins. All pumps belong to the high-performance type manufactured by RM or Rovatti or Caprari.

The peculiar features hallmarking our engine-driven pumps are:

- Heavy-duty sheet plate frame on wheel trolley with three adjustable supports and disassemblable drawbar.

- Built-in tank into the frame with a 450/480 litre capacity outfitted with polluting liquids retaining tank and fuel level gauge.

- Right-hand and left-hand fuel hubs outfitted with plug with key.

- Roof, side guards and bonnets made up of sheet plate and outfitted with key lock.

- Diesel engine and pump flanged together with high-quality flexible coupling joint.

- Anti-vibrating supports between engine, pump and frame.

- Battery container partially made up of stainless steel and lighting lamp of pump zone.

- High-quality electronic control panel from Elcos CIM/CEM or EasyMop or Idromop.

“cool water motor” patented system

|

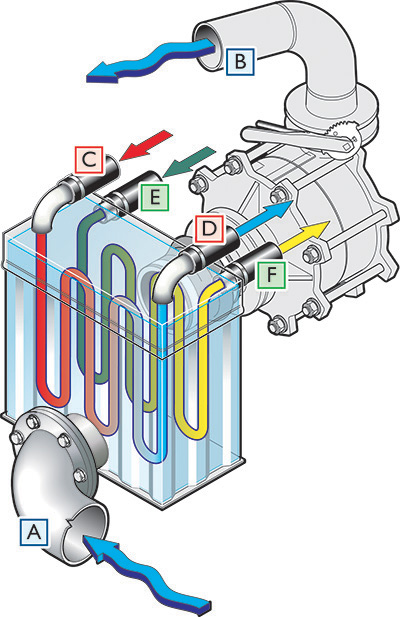

RM heat exchanger is fully manufactured in INOX 304 steel; it is assembled at the pump inlet and its job is to cool the engine coolant (closed circuit and controlled by the original thermostatic valve of engine) through thermal exchange with the irrigation water sucked by the pump. This system allows saving approximately 8% of engine power thanks to the elimination of the blowing fan and radiator. Moreover, the system makes benefit from a drastic drop in noise thanks to the absence of fan/radiator (approximately 77.5 dB at 8 metres with engine at 1650 rpm). A further advantage for the user is the absence of any radiator maintenance and/or cleaning, thus leaving out the bothersome periodical maintenance operations. Engines outfitted with intercooler are equipped with two coil exchangers in order to perform a thermal exchange between suction water and the air coming from the turbocharger and directed towards the engine. RM heat exchanger is protected by International patent and it is supplied as optional preferably with JCB Dieselmax engines. |

|

|

A Water inlet for irrigation. B Water outlet for irrigation. C Engine liquid inlet. D Engine liquid outlet. E Turbocharger air inlet. F Turbocharger air outlet. |

|

DIMENSIONS AND TÉCNICA TABLE

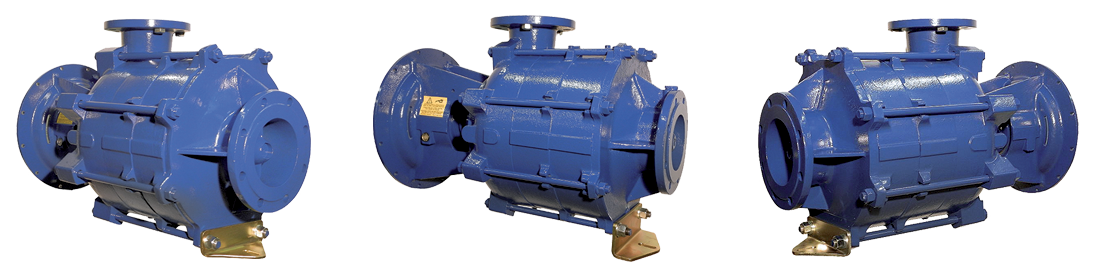

RM high-performance pumps from a brand new project aimed at manufacturing a very high quality product which is constant over time, innovative and with a high yield. They are horizontal axle multicellular centrifugal pumps suitable for being directly coupled with Diesel engines with SAE3 flange or bare shaft for electric motors.

RM pumps are especially heavy-duty machines equipped with very performing components which are oversized in order to stand the high mechanical stress produced by the latest generation Diesel engines. Those pumps ensure a very long life, even working in heavy-duty situations. All the components are manufactured in Italy with certified materials and assembled in dedicated areas

The main features of RM pumps are the following:

- Axle support with increased size and primary bearings in class A, oil lubricated.

- High-resistance hardened and tempered stainless steel, oversized with stress shielding in the diameter heads; protective stainless steel bushing near the packing seal.

- Fastening of the impellers and flexible coupling joint onto the shaft through high-torsional stiffness patented torque (FGP). 4. Packing seal or mechanical seal upon request.

- The range of the new RM pumps consists of:

|

Model |

Max delivery |

Max pressure |

No. impellers |

Max. output |

|

APS 100-125 B |

3.600 |

28,1 |

1-2-3-4-5 |

78 |

|

APS 125-175 A |

4.000 |

25,1 |

1-2-3-4-5 |

81 |

|

APS 125-175 B |

6.500 |

23,6 |

1-2-3-4-5 |

83 |

|

APS 150-500 B |

12.500 |

12,0 |

1 |

84 |

|

APS 150-500 B2 |

10.600 |

21,8 |

2 |

83,5 |

Download the documents

Optionals

- Frame with 600/650 lt. or 1,000 lt. increased tank.

- Bonderised tank.

- Kirpy type primer (manufactured by RM for high performance) to quickly fill the suction hose through the engine exhaust gas pressure.

- Primer with 12V electrical pump; operating in depression (as optional with fully automated system for unit switching on from remote control).

- Gooseneck on the fixed pump delivery with d. 4” or 5” pipe and 180° swiveling final joint.

- Soundproof cabin with internal exhause

- Suction arm with manual winch and length-adjustable.

- Suction arm with winch and hydraulic rotation outfitted with 2-lever hydraulic distributor and quick joints to the tractor.

- Hydraulic standing feet (no. 3).

- GSM modem for electronic control panel.

- Idromop control panel with automatic regulation of water pressure (optional with GSM/GPRS for remote control from mobile phone or Web).