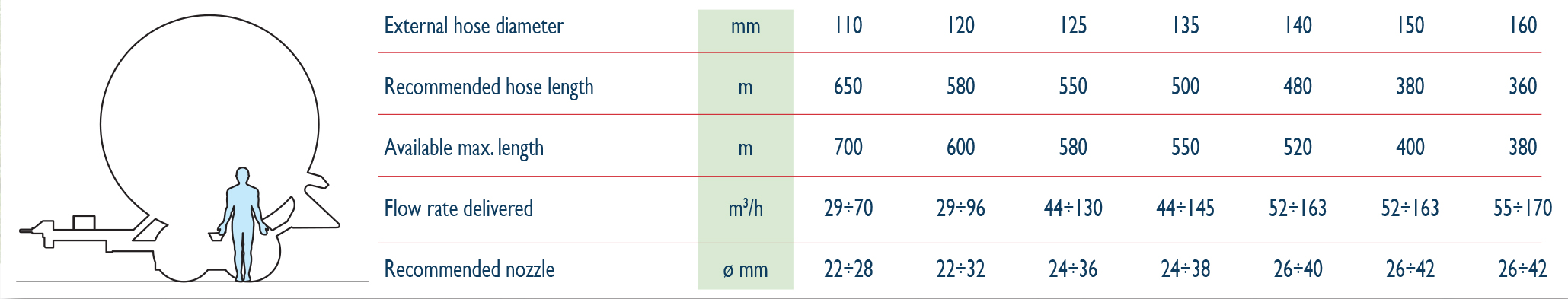

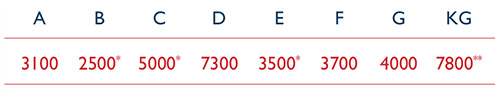

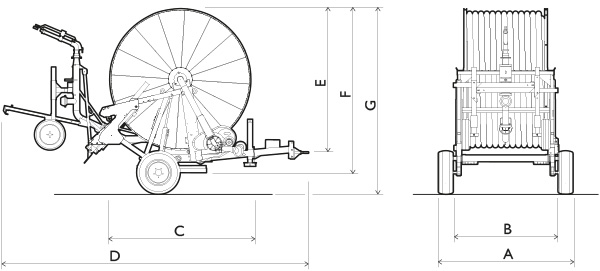

DIMENSIONS AND TÉCNICA TABLE

* minimum measures for transport ** (ø 140/450 mm)

* minimum measures for transport ** (ø 140/450 mm)

Standard equipment

- Flow-distributor turbine with built-in by-pass.

- 4-speed gearbox with shafts completely in oil bath.

- PTO for fast hose rewinding.

- Braking system to unwind the hose with fully automatic operation.

- Automatic speed compensator according to the hose winding diameter.

- Anti-slackening hose safety device.

- Safety device to stop the machine if the hose winds unevenly.

- Electronic hose rewinding speed measuring device.

- Digital clock.

- Worm screw hose turning system with micrometric regulation and double guide.

- Reel support on ball bearings and lipped retention ring with stainless steel bushing.

- Frame swivelling on a ball bearing centre plate through 360°.

- Automatic trolley lifting at the end of sprinkling by means of VertiLift™ system.

- Hydraulically controlled rear anchoring brackets, independent on both sides.

- Bar base hydraulically controlled through spool valve.

- Two-wheeled cast iron sprinkler trolley.

- Adjustable trolley track and wheel height.

- SIME sprinkler with slow return and set of nozzles

- Pressure-gauge in glycerine bath on the machine.

- Pressure-gauge in glycerine bath on the sprinkler (SIME).

- Ball joint on sprinkler trolley.

- Sprinkler trolley ballasts.

- Adjustable bar eye.

- Hot-dip galvanized structure (painted reel).

- Six-lever spool valve on swivelling arm

- Hydraulic rotation of bearing centre plate with six levers

- Engine-driven pump unit built into the machine structure.

- Vacuum pump to empty the hose.

- Dip tube ø 150 with revolving joint and basket ø 550.